As the repetition rate of high-power lasers rises, the demand for large numbers of targets will rise. In addition, there is an increasing demand for targets with micron-scale structures. MEMS (Micro-Electro-Mechanical Systems) processing is a solution to both requirements. To meet these demands, Scitech Precision has now brought much of its MEMS processing

capability in-house with the recent constr

uction of a new Class 100 cleanroom and the installation of microlithography and deep silicon etch tools.

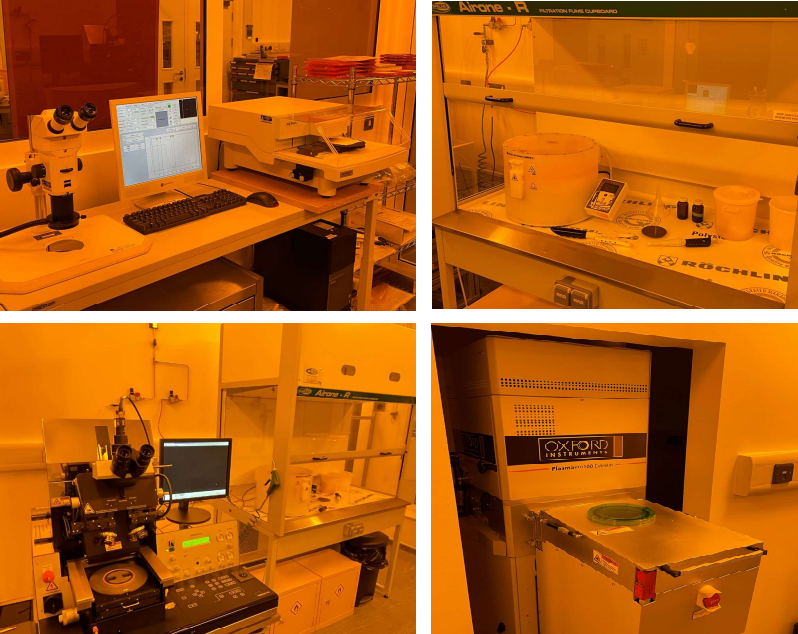

The lab houses key tools for MEMS processing; photoresist spin-coater, mask

aligner resist exposure tool, deep silicon etch (DSE) tool, plus various characterisation tools including microscopes and a profilometer. Gold safelighting allows use of light sensitive materials such as photoresist.